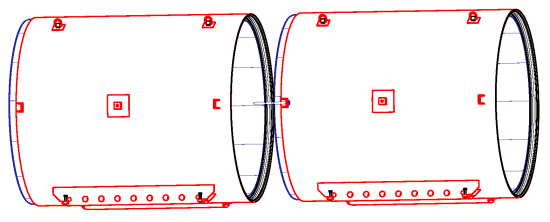

LARGE-PROFILE PIPES WITH CAST BASALT LINING AND BUILT-IN SEALING

Large-profile pipes with cast basalt lining are intended for placement in a trench or tunnel for sewage and rainwater. 360-degree cast basalt lining guarantees excellent protection against abrasion and biogenic corrosion. The service life is basically unlimited.

The basalt lining is composed of calibrated radial segments(precise machining of each piece) usually with a wall Thickness of 40mm. To guarantee the highest quality and precision, basalt segments are first glued into precise rings, and the individual rings are then glued to the required length (usually 2m). A special epoxy glue with basalt filler is used for gluing. The gap between the segments is approx. 0.5mm. Subsequently, the basalt tube is inserted into the prepared steel casing, and the space in between is filled with a special cement grout.